Finite Element Analysis (FEA)

Finite Element Analysis (FEA)

What Is FEA or Finite Element Analysis?

FEA is a numerical technique for solving engineering problems described by a set of partial differential equations.Throughout Brisbane, the types of engineering problems that could be solved using FEA analysis services are in the fields of machine design, acoustics, electromagnetics, soil mechanics, fluid dynamics, structural engineering, vibrations and thermal analysis to name a few.

Where Do We Use FEA?

At Fernandes &Associates we use FEA for the following:

> Providing a detailed structural analysis of plate structures like bins, vessels and chutes

> Determining the impact and fatigue resistance of machine components

> Optimizing material usage and reducing component weights and costs

> Carrying out structural analyses to determine safety and compliance to National Construction Codes and Australian Standards.

Why Choose Fernandes and Associates for FEA?

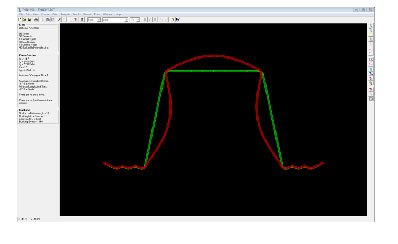

FEA is a very powerful tool for engineering analysis and is used to solve problems from very simple to very complex. Our design engineers use FEA during the product development process to analyse the design at various stages. Time constraints and limited availability of product data call for many simplifications and assumptions in creating the analysis models. Experienced analysts can use FEA to solve advanced problems such as vehicle crash dynamics, metal deformation or response of light gauge steel structures to wind loading.

Regardless of the complexity of the problem, the fundamental steps in any FEA analysis services in Brisbane are always the same. The starting point for any analysis is to create the geometric model followed by defining material properties, loads and restraints. The next step is the discretization process where the geometry is broken up into small and simple shaped entities, called finite elements. This process is commonly known as meshing.

Although FEA is a powerful tool to solve engineering problems, there could be errors in the results caused by modelling errors due to simplifications, in-appropriate boundary conditions or symmetry, or making wrong assumptions. When preparing computer models, we try to get the model to replicate real-life conditions. However, it is not possible to get this 100% accurate but we could create a model where the results are accurate enough to give a fair indication of the real-life conditions. The results obtained for complex problems using FEA can depend on the knowledge, experience and skills of the engineer.

We, at Fernandes & Associates use FEA for structural analysis. The steps involved in using FEA are as follows:

1. Create the geometric model

2. Assign material properties, loads and restraints to the model

3. Create finite elements of the model by meshing the model

4. Solve the problem

5. Analyse the results. The analysis of results can be the most difficult step. FEA can provide detailed results and data. Proper interpretations of the results and data requires a good understanding the assumptions, simplifications and errors introduced when building the model, creating the mesh and solving the finite element model.

How Can We Help?

A major part of Fernandes & Associates’ projects involves the application of FEA and other advanced analyses techniques.Our engineers are highly skilled in solving engineering problems. They will decide the best approach and which engineering tools to use to find solutions to the problems. The suites of engineering software we use include the following:

> SpaceGass

> SolidWorks Simulation

> Strand7

> PRFELB

> PURLIN

> THIN WALL

The software we choose to solve a particular problem depends on the complexity of the problem and the accuracy of the results we require. Some software require more time to model and solve without any added benefits - it comes down to using the right tool for the right job (or fitness for purpose). Some engineering problems can only be solved by using FEA and/or testing. Some of the results obtained by using FEA can only be validated by testing.

All Services

- Mechanical Engineering

- Structural engineering

- Cable Structures

- Steel House Framing

- Mechanical Design and Drafting Services

- Finite Element Analysis (FEA)

- Vibration and Failure Analysis

- Forensics Expert Witness Reports

- Crane Inspection Services

- Crane Repairs

- Workplace Health and Safety

- Non Destructive Testing (NDT)

- Hydraulics - Roof Drainage Systems

- Professional Consulting Engineers in Brisbane, Queensland