-

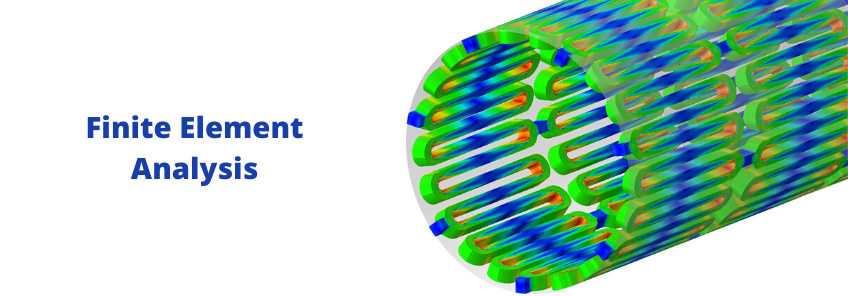

How is FEA Analysis Services Significant in CAD?

By Fernandes & Associates Pty Ltd 03 Jun 2020It is common for the engineers in Brisbane to consider simulation modelling techniques that are Finite Element Analysis for automating and simplifying the testing. It helps in reducing the materials used for iterative prototyping that will next be used in actualization. Finite Element Analysis services in commonly used by the CAD engineers in Brisbane for simulating "stress" on their designs.

1. What does Finite Element Analysis mean?

Finite Element Analysis is applied as a numeric technique for solving the engineering solutions along with an array of calculations based on physics. For instance, while designing a bridge, the engineers will have to make a prediction on the structure's behaviour under the load. Although they might know the equation systems describing the structural stresses’ distribution yet they cannot solve easily and directly for the complicated structure like a bridge.

Hence, the system should be broken down into finite elements or the small elements where the calculations are easily done and solved. Finite elements are one, two, and three dimensional. Whatever are the construction needs, the FEA Analysis services are must in Brisbane.

2. What are the Principles of FEA?

- Finite Element Analysis method helps in engineering for computing the right boundary and field problem solutions.

- The field is the representation of the physical features as its main domain.

- The variables of interest are the field variables governed by the differential equation.

- On the finite element, a node is a specific point containing the field variable's value, which is, be calculated explicitly. These values help in computing the values at non-nodal points by means of values interpolation at the nodes by using the shape functions.

3. The General Process Followed in FEA

i. Pre-processing for the need of Manufacturing

At this stage, the engineers define the material properties, domain problem, mesh model, geometric properties, element types, and boundary conditions. At this particular stage, the engineers simplify the problem to derive accurate results. For instance, before simulation, there are numerous fillets and holes along with other features in the CAD model. The most important among them are the features hogging the computational resources and increasing render times. The CAD engineers remove the unwanted features for speeding up the simulations. They are able to do it manually, along with the designers by using CAD defeaturing options on Spatial software. The major advantage of automating the CAD process is the human errors are verily reduced.

ii.Solution

In CAD, the computations are created to suit the field variables unknown values. These values are useful for computing the derived variables like the stresses and the reaction forces.

iii.Post Processing

Plotting, sorting, and printing is the ultimate activities where the engineers implement the selected results as solutions to the finite element analysis.

4. How is FEA Applicable in CAD?

FEA is a powerful feature commonly used in CAD design.

- FEA is integral to CAD to analyze a particular object through using the finite elements including the small triangular and rectangular shapes.

- For analyzing the entire project, analysis is made for each individual finite element present in the total object network. Next, they combine the outcomes for plotting the complex object's overall behaviour.

- Analysis can be made for each element for specific property thresholds which include the dynamic, stress-strain, and the characteristic based on where they apply it.

The engineers can easily define each element as well as network structure in the CAD workflow as required in the design.

Although FEA is predictive, yet it is not always affirmative. It helps the engineers with a view that how might the designs react while facing the imposed stresses at the time of cutting on the physical testing costs. But it will not ascertain whether a design is going to tolerate the simulated stress with surety. Nevertheless, various CAD software uses the FEA feature to design accurate structures in any engineering field.

0 Comment

Leave a Comment

Your email address will not be published. Required fields are marked *